2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

Rock drill bit is the part that directly breaks rock mass, and is used to break the rock through the impact of the blades and buttons in various solid rocks to form different diameters holes. According to different requirements of operation and construction, the drill bit has different classification methods. According to shape of carbide inserts, rock drill bit can be divided into chilsel drill bit, button bit, and chip-button composite drill bit. Although there are many kinds of rock drill bits, their quality depends on advanced and reasonable manufacturing technology to a large extent. So what are the manufacturing processes of different types of rock drill bits?

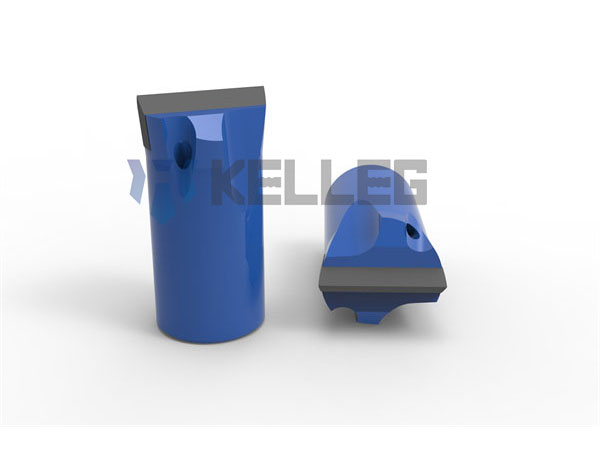

Chisel bit

Material incoming inspection→Bar steel annealing→Blanking→Flat-faced→Rough drilling inner hole→Moulding rough turning outer circle→Rough turning inner taper hole→Spot hemispherical hole→Finish turning inner taper hole→Sizing→Tooling Semi-finishing outer circle→Milling button sheet groove→Milling 110 facet→Drilling water hole→Milling powder discharge groove→Grinding button sheet→Burring, cleaning, matching sheet→Welding→Sand blasting→Grinding 2°30′ cone surface→ Finish turning skirt → Grinding 110° blade surface → Detail grinding → Finished product inspection → Rolling lettering → Tapered hole spraying soft metal or lining → Surface anti-rust treatment (painting or plastic wrapping) → Labeling → Packing and put in storage.

Tapered cross bit

Material incoming inspection→Bar steel annealing→Blanking→Flat-faced→Rough drilling inner hole→Forming rough turning outer circle→Rough turning inner tapered hole→Spot hemispherical hole→Finish turning inner tapered hole→Sizing→Drilling center Hole → Semi-finishing outer circle of the mold → Milling alloy sheet groove → Milling 110 facet → Milling powder discharge groove → Drilling side water hole → Grinding alloy sheet → Burring, cleaning, matching sheet → Welding-sand blasting → Grinding 2° 30′ tapered surface → Fine turning skirt → Grinding 110° blade surface → Detail grinding → Finished product inspection → Rolling lettering → Tapered hole spraying soft metal or lining → Surface anti-rust treatment (painting or plastic coating) → Labeling → Packing and put in storage.

Tapered button bit

Material incoming inspection→Bar steel annealing→Blanking→Flat-faced→Rough drilling inner hole→Moulding rough turning outer circle→Rough turning inner tapered hole→Saw hemispherical hole→Fine turning inner tapered hole→Flat length and short→Moulding Semi-finished turning of outer circle → Turning tooth cone surface → Inspection → Milling powder discharge groove → Milling edge tooth hole → Milling middle tooth hole → Drilling water hole → Grinding button cylindrical surface (and polishing and passivation) → Burring, cleaning, Tooth matching→Welding→Sandblasting→Finishing 3-cone surface→Finishing skirt→Detail grinding→Finished product inspection→Rolling lettering→Cone hole spraying with soft metal or lining→Surface anti-rust treatment (painting or plastic coating)→ Labeling → Packing and put in storage.

Threaded cross bit

Inspection of materials → Annealing of bar steel → Blanking → Flat-faced → Rough drilling of inner hole → Rough turning of outer circle → Flat length and short → Fine turning of threaded inner hole → Drilling of 14 water pockets → Threaded relief groove and end face of force table → Milling wave-shaped thread→Drilling central water hole→Finishing outer circle→Milling alloy sheet groove→Milling 110° edge face→Milling powder discharge groove→Drilling side water hole→Grinding alloy sheet→Burring, cleaning, fitting→Welding→Spraying Sand → Re-drilling the central water hole and flaring-grinding 3° clearance angle → Grinding 110 blade surface → Detail grinding → Finished product inspection → Rolling lettering → Surface anti-rust treatment (plastic coating or spray painting) → labeling → Packing and put in storage.

Threaded button bit

Take the D50mm thread button bit for the die forging blank shell as an example

Blanking → Die forging blanks → Blank annealing → Rough drilling of inner holes → Roughing by the die, finishing turning the outer circle → Milling cutter reaming, flat-faced, chamfering → Finishing turning head end face, side tooth cone surface → Drilling φ14mm hole → Milling thread relief → Milling wave thread → Inspection → Milling edge, top tooth hole → Milling R10 powder discharge groove → Drilling top water hole → Drilling side water hole → Burr, cleaning, tooth matching → Welding → Sandblasting → Grinding 3 °Cone surface→Detailed grinding→Finished product inspection→Anti-rust treatment→Type, labeling→Packing and put in storage