2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px请使用高分辨率宽度访问。

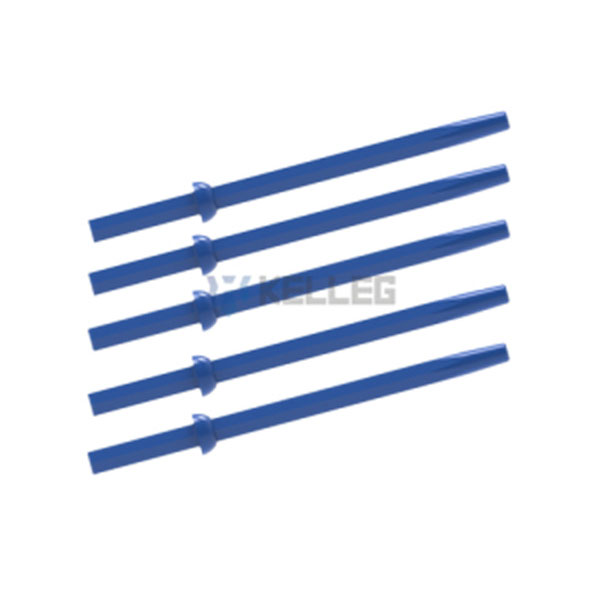

Hydraulic rock drill jumbo is a rock drilling machine widely used in large-scale infrastructure construction projects. During the rock drilling operation, its main consumable parts are drill bits, drill rods, and shank adapters. Among them, the drill rod is the most important part of rock drilling tools, and it is a kind of slender rod that is subject to complex alternating stress such as tension, compression, torsion, bending as well as wear and corrosion, and transmits dynamic energy in the form of high-frequency stress waves, so the requirements are strict for its performance and quality. So, what problems should be noted in the production of drill rods for hydraulic rock drill jumbo?

1. Quality of steel

The quality of hollow steel is one of the main reasons affecting the unsatisfactory service life of drill rods. Therefore, the quality of drill rod steel is directly related to the service life of drill rods. Drill rod is a tool that works under dynamic load conditions and must have high fatigue resistance, wear resistance, and impact resistance. These properties are related to the steel type, the purity of steel, and the uniformity of structure.

2. Production process

Reasonable production processes and manufacturing technology are the guarantees of product quality. At the same time, manufacturers should also pay attention to the upsetting extrusion process, end groove and stress ring, thread processing, heat treatment process, and anti-corrosion process in production.

①Upsetting extrusion process

The R38 thread of drill rod for hydraulic drill jumbo requires full upsetting, a straight inner hole, and no sudden change in the joint. If necessary, the bore should be machined. If the straightness of the bore fluctuates greatly during upsetting or the transition of the joint is not good, it will affect the service life of drill rod.

② End groove and stress ring

Some drill rods are designed with a flushing groove on the end of the rod and a stress ring in the transition area at the root of thread. The flushing groove can make high-pressure water enter the thread surface to cool and prevent rock dust from entering the thread. In addition to meeting the needs of high-speed machining threads, the stress ring is also conducive to increasing the flexibility of drill rod and relieving the bending stress load.

③Thread processing

The rate of thread root fracture failure at the end of the connection with drill bit is larger when drill rod is used. In cases where the hollow steel is not ideal, manufacturers should pay more attention to the quality of the threads’ machining. A reasonable tool should be selected to implement high-precision machining of the thread surface and improve the thread surface quality.

④ Heat treatment process

The purpose of heat treatment is to maximize the potential of the material, and further exploration of carburizing process and surface quenching process is very beneficial to improve the service life of drill rods.

⑤ Anti-corrosion process

The anti-corrosion process for drill rods with a length of more than 3m is to spray paint but not to deal with the water holes. Some manufacturers use overall oil immersion treatment for shorter drill rods. In general, the coating adhesion performance and anti-corrosion performance of these two methods are not very satisfactory. It is necessary to explore the process of choosing reasonably priced low-thickness chemical anti-corrosion coatings and treating both the inside and outside surfaces of drill rods.

With the rapid development of economic construction, the start rate of large construction projects in mining, transportation, hydropower, building materials, national defense, and other fields is increasing, and the number of hydraulic drill jumbos used is also rising continuously. In terms of the production of supporting rock drilling tools, manufacturers have been able to meet the market demand in terms of variety through years of technical research and development, however, there is still a big gap between the leading enterprises in the industry in terms of product performance and service life. Therefore, rock drilling tools manufacturers need to use qualified hollow steel raw materials based on strict implementation of process operating procedures, and carefully complete each process requirement.